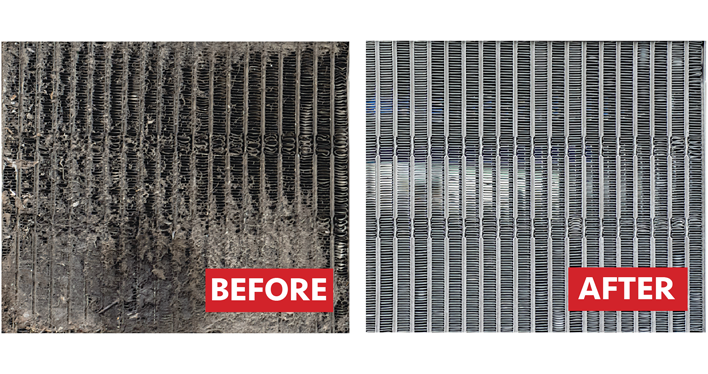

Maintaining clean HVAC coils is essential for optimal system performance and longevity. Dirty coils can significantly reduce efficiency, increase energy costs, and shorten the life of your equipment. Did you know that dirty coils can increase energy consumption by up to 30%? That’s a lot of wasted money and unnecessary strain on your HVAC system. To avoid this, it's wise to start a regular coil cleaning routine from day one, especially after installing new equipment. Think of it like a dental checkup — you might not look forward to it, but it's necessary. With the right tools and guidance, it doesn’t have to be too bad at all. HOW DO I KNOW IF MY COILS ARE DIRTY? While a scheduled maintenance plan is the best way to keep your coils in top shape, there are a few signs you can look for: • Check the air pressure drop across the coil against the design specifications. If it's higher than normal, it could mean the coil is dirty. A high refrigerant head pressure usually points to a dirty condenser coil, while low suction pressure and poor airflow may indicate a dirty DX coil. • Visually inspect the coil. If it looks grimy or clogged, it's time to clean it. Simple as that. HOW OFTEN SHOULD COILS BE CLEANED? In normal conditions, both DX evaporator coils and condenser coils should be cleaned once a year. However, if you're in an area with high cooling demand or lots of airborne debris, such as cottonwood fuzz or salt air, more frequent cleaning is needed. Also, coils with high fin density tend to trap dirt more easily, so they require more attention. Here are some general guidelines: Condenser coils under extreme conditions: Clean quarterly Units near salt water (within one mile): Clean monthly DX evaporator coils in corrosive environments: Clean quarterly HOW TO CLEAN A COIL: Before starting any cleaning, always disconnect and lock out the power supply to prevent accidental startup. This step is crucial for safety. Take care not to get motors or electrical components wet. Remove large debris first, and gently straighten any bent fins before cleaning. Use a pressure washer with a 25–40 degree nozzle, making sure not to damage the delicate aluminum fins. Use non-acidic, alkaline-based cleaners like Nu-Brite for condensers and Evap Pow’r-C for evaporators. These products help lift dirt from deep within the coil. If you must use an acidic cleaner, follow instructions carefully and rinse thoroughly — improper use can damage the coil. If a gentle scrub is needed, use only a soft-bristled brush. After cleaning, rinse the coil thoroughly with a power washer or garden hose. Never skip this step — residue can cause long-term issues. Always read and follow manufacturer instructions when using any cleaning product. Using the wrong chemicals can lead to costly repairs or even personal injury. USE STEAM TO REDUCE MESS For indoor coils, steam cleaning is an excellent alternative. It effectively removes dirt without leaving excess water behind, which is great for sensitive areas. Just be careful not to over-saturate electrical components. When using steam, apply it at low pressure and keep the stream parallel to the fins to avoid damaging them. A LITTLE MAINTENANCE GOES A LONG WAY Properly maintained commercial HVAC coils can last many years. On average: Quality replacement coils can last just as long as OEM parts, sometimes even longer due to improved materials. However, environmental factors and location can still impact their lifespan. WHAT IF MY COIL IS COATED? Coated coils offer extra protection against corrosion, but they still need regular cleaning. Don't assume that coating makes them immune to dirt — they still require the same level of maintenance as uncoated coils. Keeping them clean ensures the coating remains effective over time. Need help or have questions about your HVAC coils? Contact us anytime — we’re here to help! Variable valve timing (VVT) solenoid or oil control valve controls the oil flow according to the engine speed and load. VVT solenoid is a vital part of the variable valve timing system. Nissan Variable Valve Timing,Nissan Vvt Solenoid,Vvt Solenoid Nissan Altima,Vvt Solenoid Valve Wenzhou Zhongking Parts Co.,ltd , https://www.oemvvt.comHow to Clean Commercial HVAC Coils

Written by: Stephen Barzelatto

Vice President of Nationwide Coils

The Oil Control Valve (OCV) is a a critical part used in every engine that is fitted with variable valve technology (VVT). A single control valve will regulate the supply of oil to a designated VVT hub, to advance or retard the timing by altering the camshaft angle position. Controlled by the ECU, the OCV receives electrical signals, instructing it to adjust the oil flow as required, in accordance to current driving conditions.

How to Clean Commercial HVAC Coils