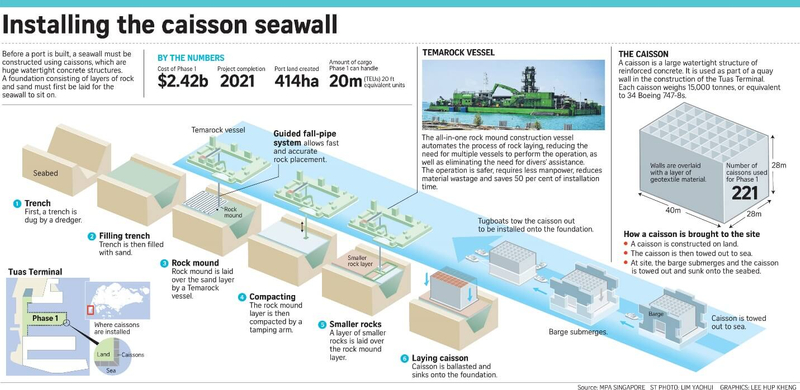

We previously covered Singapore's maritime significance and why the Mega Tuas Port is a game-changer for the country. You can check out that article here.  As of now, Phase 1 of the Mega Tuas Port has successfully installed a total of 221 caissons and is on track to complete all reclamation work by 2021, with around 2,000 workers and supervisors on site. Meanwhile, Phase 2 has already started and is progressing steadily.  The Mega Tuas Port is designed to handle ultra-large container vessels with a capacity of up to 24,000 TEU, supported by a water depth of 24 meters. Once operational, it will be capable of accommodating any size of cargo vessel in the world, making it the largest port globally.  Discover more about the key construction equipment used in this massive project.   The Maritime and Port Authority of Singapore (MPA) is using Caisson Technology to build the port. This method involves prefabricated, hollow concrete structures that are sunk underwater and filled with concrete to form a solid foundation.  Caisson technology has been used for centuries in underwater construction, especially for ports and bridges. For the Mega Tuas Port, caissons are being used to create the breakwater and seawall for land reclamation.   This approach is safer and more efficient than traditional methods like piling. It’s also being used for all remaining phases of the project. The caissons used at Tuas Terminal are among the largest in the world—each weighing 15,000 tonnes, measuring 40 meters long, 28 meters wide, and 28 meters high, which is as tall as a 10-story building.   The image above illustrates how the seawall is constructed to enclose the port area. Once the watertight wall is in place, land reclamation inside the structure begins.  To install the caissons, a rock mound foundation must first be laid on the seabed. Here’s how the process works: “TEMAROCK is an advanced, all-in-one rock mound construction vessel. Unlike traditional methods that require multiple vessels and divers, TEMAROCK automates the entire process, improving efficiency and safety.†  Meanwhile, the caissons themselves are being fabricated on-site. Two caisson fabrication yards have been built side by side to speed up production. Unlike other projects that cast caissons on floating docks, this method allows two caissons to be made simultaneously.  “To streamline the process, an Automatic Rebar Machine using Robotics System (ARMS) is used. This system automates the cutting and bending of reinforcement steel bars, reducing manual labor and increasing safety.†  Once the caissons are in place, the area within the seawall is reclaimed to create solid land. After that, the port terminal is built with all necessary equipment and facilities.  The project also emphasizes sustainability. For example, excavated earth from other construction sites is reused, reducing the need for sand by up to 70% in Phase 1 and 50% in Phase 2. MPA estimates this will save around S$2 billion in costs.  Here’s a short video showing the progress of Phase 1 construction:  Don’t forget to like and share our Facebook page! bit.ly/34MdSFh, and we’ll keep bringing you more interesting content.   We are Singapore’s first intelligent digital platform transforming the traditional construction equipment rental experience into a touchless, modern solution. Learn more with us! Towable Backhoes,Mini Backhoe,Backhoe Excavator,Tractor Backhoe,Compact Excavator Mower Changzhou Kafurter Machinery Co., Ltd , https://www.kafurter.com

So, how exactly is the Mega Tuas Port being built?

RENT EQUIPMENT HERE

The Construction of Mega Tuas Port