A cap screws usually features internal and external socket drive heads with different shapes relying upon the type. Below the cap screw head a fully or partially threaded shaft with a bevel end. It is primarily used for machinery, automotive and industrial manufacturing applications because it offers high-yield strength and durability.

Table of contents

- Different Types of Cap Screws and Their Applications

- Mechanical Properties and Grades of Socket Head Cap Screws

- ASTM Standards of Cap Screws

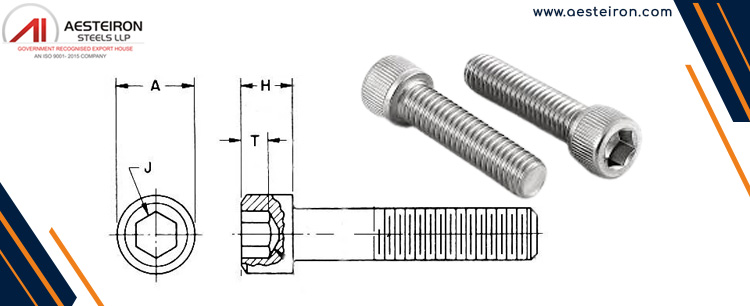

- Socket Cap screw Sizes as per ASME B18.3

- Hexagon Socket Head Screws Size Chart (BS 2470)

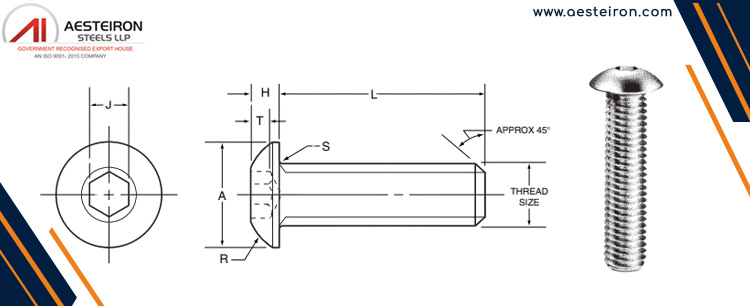

- Button Head Cap Screws Dimension

- Recommanded Tightning Torque for Button Head Screws

- Advantages of Using Cap Screws in Machine Parts and Clamping

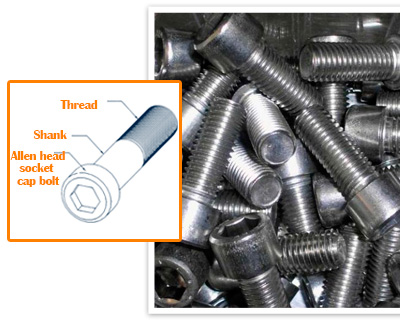

- How To Measure An Allen Head Socket Cap Bolt

- Shank and Thread Length Measurements for Allen Head Cap Bolt Lengths

- Torque Specs For Socket Head Cap Screws

- Cap Screw Applications

- Knurled Head Cap Screws Certification

- Cap Screws Metric DIN and ISO Standards

- Cap Screws vs Socket Screws

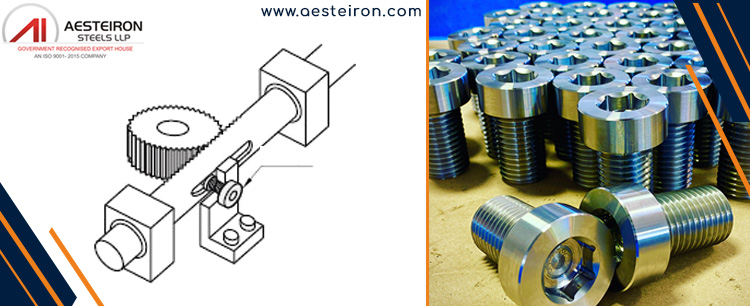

- Manufacturing Process Socket Head Cap Screws

Different Types of Cap Screws and Their Applications

| Types of cap screw |

|

Head shape |

Drive types |

Application |

| Flat head cap screws |

|

Countersunk |

Hex or Socket |

Used in applications requiring flush surfaces, countersunk holes |

| Hex head cap screws |

|

Hexagonal |

Hex or Socket |

heavy machinery, structural applications |

| Socket head cap screws |

|

Cylindrical |

Hex Socket |

Precision applications, where space is limited |

| Button head cap screws |

|

Rounded |

Hex or Socket |

where a lower profile is needed, aesthetic purposes |

| Pan head cap screw |

|

Rounded with a flat underside |

Hex or Socket |

General-purpose, where a large bearing surface is needed |

| Slotted Hex Cap Screw |

|

Hexagonal |

Slotted or Hex |

where the ability to adjust with a slotted screwdriver is desired |

| Torx Cap Screw |

|

Star-shaped |

Torx |

high-torque applications |

| Low Head Socket Cap Screw |

|

Low-profile cylindrical |

Hex Socket |

For applications with limited vertical space |

| Hex Flange Cap Screw |

|

Hexagonal with a flange |

Hex or Socket |

automotive and machinery applications |

| Tri-Wing Cap Screw |

|

Triangular winged |

Tri-Wing |

Security applications |

Flat head cap screws are manufactured as per ISO 4762 standard

Mechanical Properties and Grades of Socket Head Cap Screws

| Grade |

Strength |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Equivalent SAE Grade |

| 8.8 |

Medium strength |

800 |

640 |

5 |

| 10.9 |

High Strength |

1000 |

900 |

8 |

| 12.9 |

Very High Strength |

1200 |

1080 |

9 |

ASTM Standards of Cap Screws

- ASTM F835 (Alloy Steel Flat Countersunk and Socket Button Head Cap)

- ASTM F912M (Alloy Steel Socket Set Screws (Metric))

- ASTM F912 (Alloy Steel Socket Set Screws)

- ASTM F837M (SS Socket Head Cap Screws (Metric))

- ASTM F837 (SS Socket Head Cap Screws)

Round socket head screws are available in wide range of sizes

It also known as round head cap screws and a circle head screws. It is extremely usually useful form of fasteners which serves many different advantages. Below given are few areas where it is used in.

It is used mostly to put electronics element together. It is very high in toughness and be used as security fasteners as well. Without the usage of accurate tools, it can be difficult to install and un-install.

Construction: It is been easily available, cost-effective, value for money material, it is often used for common construction purpose.

Carpentry: It is easy to use, tough, and not too hard to drill, it is often used for woodworking.

Fastening thin material: Due to its unique shape and it has nearly flat tops, it is ideal for fastening thin material to other kinds of material.

Socket Cap screw Sizes as per ASME B18.3

| Thread Size |

0 |

1 |

2 |

3 |

4 |

5 |

6 |

8 |

10 |

01/4 |

5/16 |

03/8 |

7/16 |

01/2 |

05/8 |

03/4 |

07/8 |

1 |

| T.P.I UNF |

80 |

72 |

64 |

56 |

48 |

44 |

40 |

36 |

32 |

28 |

24 |

24 |

20 |

20 |

18 |

16 |

14 |

12 |

| T.P.I UNC |

|

64 |

56 |

48 |

40 |

40 |

32 |

32 |

24 |

20 |

18 |

16 |

14 |

13 |

11 |

10 |

9 |

8 |

| Head Dia (Max) A |

0.096 |

0.118 |

0.14 |

0.161 |

0.183 |

0.205 |

0.226 |

0.27 |

0.312 |

0.375 |

0.469 |

0.562 |

0.656 |

0.75 |

0.938 |

1.125 |

1.312 |

1.5 |

| Key Engagement (Min) T |

0.025 |

0.031 |

0.038 |

0.044 |

0.051 |

0.057 |

0.064 |

0.077 |

0.09 |

0.12 |

0.151 |

0.182 |

0.213 |

0.245 |

0.307 |

0.37 |

0.432 |

0.495 |

| Head Height (Max) H |

0.06 |

0.073 |

0.086 |

0.099 |

0.112 |

0.125 |

0.138 |

0.164 |

0.19 |

0.25 |

0.312 |

0.375 |

0.438 |

0.5 |

0.625 |

0.75 |

0.875 |

1 |

| Key Size J |

0.05 |

1/16 |

5/64 |

5/64 |

3/32 |

3/32 |

7/64 |

9/64 |

5/32 |

3/16 |

01/4 |

5/16 |

03/8 |

03/8 |

01/2 |

05/8 |

03/4 |

03/4 |

| Thread Length (Max) |

0.62 |

0.77 |

0.8 |

0.83 |

0.99 |

1 |

1.05 |

1.19 |

1.27 |

1.5 |

1.71 |

1.94 |

2.17 |

2.38 |

2.82 |

3.25 |

3.69 |

4.12 |

| Thread Length (Min) |

0.5 |

0.62 |

0.62 |

0.62 |

0.75 |

0.75 |

0.75 |

0.88 |

0.88 |

1 |

1.12 |

1.25 |

1.38 |

1.5 |

1.75 |

2 |

2.25 |

2.5 |

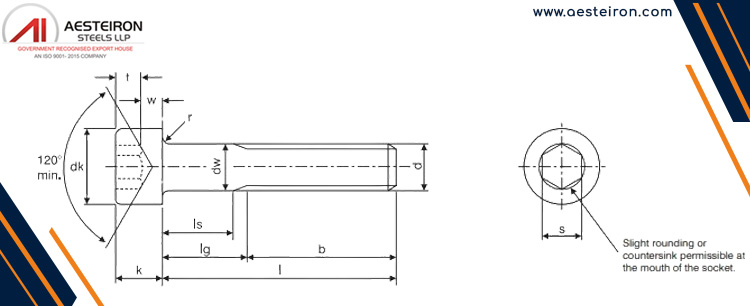

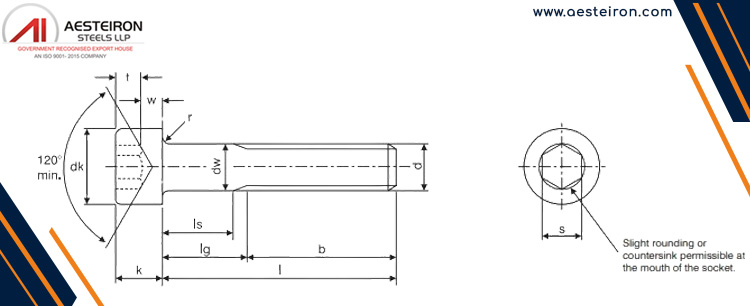

Hexagon Socket Head Screws Size Chart (BS 2470)

| Nominal size and thread dia d |

|

0 |

2 |

1 |

3 |

5 |

4 |

6 |

10 |

8 |

12 |

5/165/16 |

1/41/4 |

3/83/8 |

43467 |

43724 |

7/167/16 |

43593 |

43654 |

43528 |

1 |

1.1/4 |

1.1/8 |

1.3/8 |

1.3/4 |

1.1/2 |

2 |

| Head dia dk |

max.max. |

0.096 |

0.14 |

0.118 |

0.161 |

0.205 |

0.183 |

0.226 |

5/165/16 |

0.27 |

0.343 |

7/167/16 |

3/83/8 |

9/169/16 |

43528 |

0.812 |

5/85/8 |

43654 |

1.1/8 |

1 |

1.5/16 |

1.75 |

1.5 |

1.875 |

2.5 |

2 |

2.75 |

| min.min. |

0.093 |

0.136 |

0.114 |

0.157 |

0.2 |

0.178 |

0.221 |

0.306 |

0.265 |

0.332 |

0.429 |

0.367 |

0.553 |

0.739 |

0.795 |

0.615 |

0.863 |

1.111 |

0.987 |

1.297 |

|

|

|

|

|

|

| Pitch of thread |

UNC |

— |

56 |

64 |

48 |

40 |

40 |

32 |

24 |

32 |

24 |

18 |

20 |

16 |

13 |

12 |

14 |

11 |

9 |

10 |

8 |

7 |

7 |

6 |

5 |

6 |

4.1/2 |

| UNF |

8000% |

6400% |

7200% |

5600% |

4400% |

4800% |

4000% |

3200% |

3600% |

2800% |

2400% |

2800% |

2400% |

2000% |

1800% |

2000% |

1800% |

1400% |

1600% |

14-Dec |

1200% |

1200% |

1200% |

– |

1200.00% |

– |

| Thread length b |

min.min. |

0.5 |

0.625 |

0.625 |

0.625 |

0.75 |

0.75 |

0.75 |

0.875 |

0.875 |

0.875 |

1.125 |

1 |

1.25 |

1.5 |

1.625 |

1.375 |

1.75 |

2.25 |

2 |

2.5 |

|

|

|

|

|

|

| Dia of unthreaded shank dw |

max.max. |

0.6 |

0.086 |

0.073 |

0.099 |

0.125 |

0.112 |

0.138 |

0.19 |

0.164 |

0.216 |

0.3125 |

0.25 |

0.375 |

0.5 |

0.5625 |

0.4375 |

0.625 |

0.875 |

0.75 |

1 |

1.25 |

1.125 |

1.375 |

1.75 |

1.5 |

2 |

| min.min. |

0.0568 |

0.0822 |

0.0695 |

0.0949 |

0.1202 |

0.1075 |

0.1329 |

0.184 |

0.1585 |

0.21 |

0.3053 |

0.2435 |

0.3678 |

0.4919 |

0.554 |

0.4294 |

0.6163 |

0.8647 |

0.7406 |

0.98861 |

1.2336 |

1.1086 |

1.3568 |

1.7295 |

1.4818 |

1.978 |

| Width across flats s |

nom.nom. |

0.05 |

1/161/16 |

0.05 |

5/645/64 |

3/323/32 |

5/645/64 |

3/323/32 |

5/325/32 |

1/81/8 |

5/325/32 |

7/327/32 |

3/163/16 |

5/165/16 |

43532 |

43532 |

5/165/16 |

43467 |

43724 |

43724 |

43593 |

43528 |

43528 |

43528 |

1.1/4 |

1 |

1.3/8 |

| Thickness of head k |

max.max. |

0.06 |

0.086 |

0.073 |

0.099 |

0.125 |

0.112 |

0.138 |

0.19 |

0.164 |

0.216 |

5/165/16 |

1/41/4 |

3/83/8 |

43467 |

0.562 |

7/167/16 |

43593 |

43654 |

43528 |

1 |

1.25 |

1.125 |

1.375 |

1.75 |

1.5 |

2 |

| min.min. |

0.057 |

0.083 |

0.07 |

0.095 |

0.121 |

0.108 |

0.134 |

0.185 |

0.159 |

0.201 |

0.306 |

0.233 |

0.368 |

0.492 |

0.553 |

0.43 |

0.616 |

0.864 |

0.74 |

0.988 |

1.236 |

1.111 |

1.36 |

1.734 |

1.485 |

1.983 |

| Radius under head r |

max.max. |

0.007 |

0.008 |

0.007 |

0.008 |

0.01 |

0.009 |

0.01 |

0.014 |

0.012 |

0.014 |

0.017 |

0.014 |

0.02 |

0.026 |

0.03 |

0.023 |

0.032 |

0.044 |

0.039 |

0.05 |

|

|

|

|

|

|

| min.min. |

0.003 |

0.004 |

0.003 |

0.004 |

0.006 |

0.005 |

0.006 |

0.009 |

0.007 |

0.009 |

0.012 |

0.009 |

0.015 |

0.02 |

0.022 |

0.018 |

0.024 |

0.034 |

0.03 |

0.04 |

|

|

|

|

|

|

| Wall thickness w |

min.min. |

0.019 |

0.028 |

0.023 |

0.032 |

0.04 |

0.036 |

0.044 |

0.061 |

0.052 |

0.074 |

0.1 |

0.08 |

0.12 |

0.16 |

0.18 |

0.14 |

0.2 |

0.28 |

0.24 |

0.32 |

0.475 |

0.428 |

0.523 |

0.665 |

0.57 |

0.76 |

| Hex socket depth t |

min.min. |

0.025 |

0.038 |

0.031 |

0.044 |

0.057 |

0.051 |

0.064 |

0.09 |

0.077 |

0.11 |

0.151 |

0.12 |

0.182 |

0.245 |

0.276 |

0.213 |

0.307 |

0.432 |

0.37 |

0.495 |

0.62 |

0.557 |

0.682 |

0.87 |

0.745 |

0.995 |

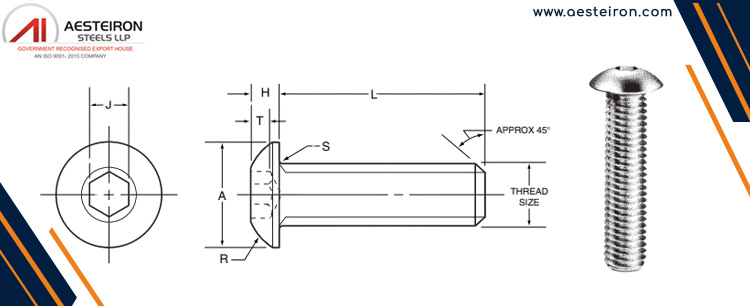

Check dimensions and tensile strength of button head cap screws

It has the similar shape of a pan head with the driver of a socket head. It is manufactured for fastening applications, it doesn’t has strength like standard socket screws. The socket driver is perfect for low withdrawal applications which needs a large area of clamping face.

Moreover, the button heads socket drive gives higher strength than a standard phillips which gives fitting in tight area. It has low domed head with a broader bearing surface heads, which offers a finished look. It is ideal choice when accurate appearance is required.

Button Head Cap Screws Dimension

| Nom thread size |

|

M3 |

M4 |

M5 |

M6 |

M8 |

M10 |

M12 |

*M16 |

| pitch |

|

0.5 |

0.7 |

0.8 |

1 |

1,285 |

1.5 |

1.75 |

2 |

| max |

A |

5.7 |

7.6 |

9.5 |

10.5 |

14 |

18 |

21 |

28 |

| max |

H |

1.65 |

2.2 |

2.75 |

3.3 |

4.4 |

5.5 |

6.6 |

8.6 |

| min |

T |

1.05 |

1.35 |

1.92 |

2.08 |

2.75 |

3.35 |

4.16 |

5.2 |

| ref |

S |

0.35 |

0.35 |

0.45 |

0.45 |

0.45 |

0.6 |

0.6 |

0.6 |

| ref |

R |

2.95 |

4.1 |

5.2 |

5.6 |

7.5 |

10 |

11 |

15 |

| nom |

J |

2 |

2.5 |

3 |

4 |

5 |

6 |

8 |

10 |

Recommanded Tightning Torque for Button Head Screws

| Unplated |

N-m |

1.4 |

3.4 |

6.8 |

11 |

28 |

55 |

95 |

| lbf in |

12 |

30 |

60 |

97 |

248 |

486 |

840 |

| Plated |

N-m |

1.1 |

2.6 |

5.1 |

8.3 |

21 |

41 |

71 |

| lbf in |

9 |

22 |

45 |

73 |

186 |

363 |

630 |

| Tensile Load |

KN |

5.28 |

9.22 |

14.9 |

21.1 |

38.4 |

60.9 |

88.5 |

Socket Head Cap Screws are commonly used in machine parts and clamping

It is accurate for applications where there is not sufficient area to move or twist sockets. It is even known as socket head bolts. Due to its high clamping force, easy installation and guarded appearance, it is usually used for aerospace, automotive, construction, electronics and medical industries.

Advantages of Using Cap Screws in Machine Parts and Clamping

Available in ISO, DIN, ANSI standards for compatibility

| Advantages |

|

| Corrosion Resistance |

- excellent resistance to corrosion and rust

- suitable for harsh environments

|

| Precise Torque Control |

- Reducing the risk of over-tightening the fasteners

|

| High Torque Capability |

- handle higher torque compared to other fasteners

- secure and stable connection

|

| Strong Load-Bearing Capacity |

- capable of handling significant loads and stresses

|

| Low Profile Design |

- ideal for use in confined or hard-to-reach spaces

|

| Versatility |

- suitable for a wide range of applications and machinery

|

| Tool Compatibility |

- compatible with standard hex keys

- commonly available and easy to use

|

| Ease of Access |

- better access in tight spaces compared to traditional hex head bolts

|

Allen head cap screws are available in fine and course threads

Its fine threads and course threads gives several advantages for different application purpose. Its smaller pitches, which offers more threads per inches gives better bending strength and gives more accurate repairs. It makes it ideal for applications where quick assembly and disassembly is done, mainly in softer items like wood or plastic.

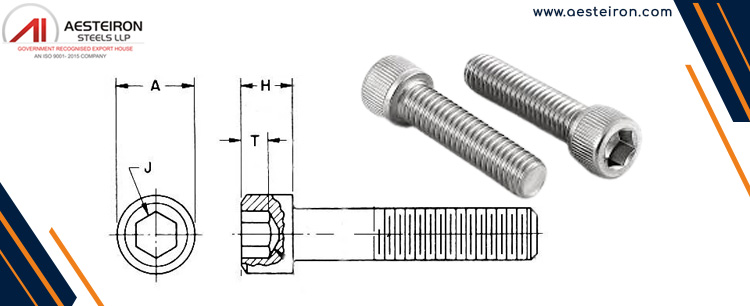

How To Measure An Allen Head Socket Cap Bolt

- Measure Outer dia by using calipers or a micrometer

- Measure Length from the bottom of the bolt head to the end of the bolt

- Use a set of Allen keys to find the matching size for the socket

- Thread pitch: measure the distance between threads

Shank and Thread Length Measurements for Allen Head Cap Bolt Lengths

| Bolt Length |

1-1/2" |

2" |

2-1/2" |

3" |

3-1/2" |

4" |

4-1/2" |

5" |

5-1/2" |

| Thread Length |

1-1/2" |

1-1/2" |

1-1/2" |

1-3/8" |

1-3/8" |

1-5/8" |

1-5/8" |

1-5/8" |

1-5/8" |

| Shank |

0" |

1/2" |

1" |

1-5/8" |

2-1/8" |

2-3/8" |

2-7/8" |

3-3/8" |

3-7/8" |

| Bolt Length |

6" |

6-1/2" |

7" |

7-1/2" |

8" |

9" |

10" |

11" |

12" |

| Thread Length |

1-5/8" |

1-5/8" |

1-5/8" |

1-5/8" |

1-5/8" |

1-1/4" |

1-1/4" |

1-1/4" |

1-1/4" |

| Shank |

4-3/8" |

4-7/8" |

5-3/8" |

5-7/8" |

6-3/8" |

7-3/4" |

8-3/4" |

9-3/4" |

10-3/4" |

Torque Specs For Socket Head Cap Screws

|

|

Size |

#0 |

#2 |

#1 |

#3 |

#5 |

#4 |

#6 |

#10 |

#8 |

1/4" |

5/16" |

7/16" |

3/8" |

1/2" |

5/8" |

7/8" |

9/16" |

3/4" |

1-1/4" |

1 |

1-1/2" |

| Socket Cap Screw |

UNC |

Nm |

|

0.86 |

0.52 |

1.25 |

3 |

1.81 |

3 |

9 |

6 |

23 |

48 |

136 |

84 |

204 |

385 |

936 |

287 |

680 |

2829 |

1414 |

4930 |

| lb ft |

|

0.63 |

0.38 |

0.92 |

2 |

1.33 |

2.5 |

6.58 |

4.58 |

17 |

35 |

100 |

62 |

150 |

283 |

688 |

211 |

500 |

2080 |

1040 |

3625 |

| UNF |

Nm |

0.3 |

0.91 |

0.54 |

1.36 |

2.72 |

2.04 |

3.85 |

10.2 |

6.57 |

26 |

52 |

148 |

95 |

234 |

431 |

1043 |

325 |

764 |

3142 |

1469 |

5549 |

| lb ft |

0.22 |

0.67 |

0.4 |

1 |

2 |

1.5 |

2.83 |

7.5 |

4.83 |

19 |

38 |

109 |

70 |

172 |

317 |

767 |

239 |

562 |

2310 |

1080 |

4080 |

| Button Head |

UNC |

Nm |

|

0.52 |

0.29 |

0.8 |

1.4 |

0.9 |

1.81 |

5.1 |

3.4 |

11 |

23 |

|

39 |

97 |

193 |

|

|

|

|

|

|

| lb ft |

|

0.38 |

0.21 |

0.58 |

1 |

0.67 |

1.33 |

3.75 |

2.5 |

8 |

17 |

|

29 |

71 |

142 |

|

|

|

|

|

|

| UNF |

Nm |

0.18 |

0.52 |

0.29 |

0.79 |

1.36 |

1.02 |

2 |

5 |

3 |

12 |

24 |

|

45 |

113 |

204 |

|

|

|

|

|

|

| lb ft |

0.13 |

0.38 |

0.21 |

0.58 |

1 |

0.75 |

1 |

4 |

3 |

9 |

18 |

|

33 |

83 |

150 |

|

|

|

|

|

|

| Flat Head (Countersunk) |

UNC |

Nm |

|

0.52 |

0.29 |

0.79 |

1.36 |

0.91 |

1.7 |

4.53 |

3.4 |

11 |

23 |

64 |

39 |

97 |

193 |

567 |

136 |

340 |

1541 |

907 |

|

| lb ft |

|

0.38 |

0.21 |

0.58 |

1 |

0.67 |

1.25 |

3.33 |

2.5 |

8 |

17 |

47 |

29 |

71 |

142 |

417 |

100 |

250 |

1133 |

667 |

|

| UNF |

Nm |

0.18 |

0.52 |

0.29 |

0.79 |

1.47 |

0.91 |

1.93 |

5.1 |

3.51 |

12 |

24 |

71 |

45 |

113 |

215 |

612 |

154 |

363 |

|

|

|

| lb ft |

0.13 |

0.38 |

0.21 |

0.58 |

1.08 |

0.67 |

1.42 |

3.75 |

2.58 |

9 |

18 |

52 |

33 |

83 |

158 |

450 |

113 |

267 |

|

|

|

| Grub Screws |

UNC |

Nm |

0.109 |

0.2 |

0.2 |

0.6 |

1.1 |

0.6 |

1.1 |

4 |

2 |

10 |

19 |

49 |

33 |

71 |

139 |

408 |

71 |

272 |

1088 |

567 |

1282 |

| lb ft |

0.08 |

0.15 |

0.15 |

0.42 |

0.83 |

0.42 |

0.83 |

3 |

2 |

7 |

14 |

36 |

24 |

52 |

102 |

300 |

52 |

200 |

800 |

417 |

943 |

Low Head Cap

Screws |

UNC |

Nm |

|

|

|

|

1.07 |

0.57 |

1.07 |

3.79 |

2.2 |

9 |

18 |

49 |

31 |

69 |

150 |

|

|

|

|

|

|

| lb ft |

|

|

|

|

0.79 |

0.42 |

0.79 |

2.79 |

1.62 |

6 |

13 |

36 |

23 |

51 |

110 |

|

|

|

|

|

|

| Shoulder Screws |

UNC |

Nm |

|

|

|

|

|

|

|

|

|

6 |

14 |

|

30 |

53 |

131 |

|

|

227 |

|

|

|

| lb ft |

|

|

|

|

|

|

|

|

|

4 |

10 |

|

22 |

39 |

96 |

|

|

167 |

|

|

|

Cap Screw Applications

- Construction

- Automotive

- Electronics

- Aerospace

- Industrial machinery

Knurled Head Cap Screws Certification

- ISO9001:2015

- AS9100D

- Non Destructive Testing

Cap Screws Metric DIN and ISO Standards

- DIN 912 (Socket Head Cap)

- DIN 916 (Socket set screw)

- DIN 7991 (Flat Head Socket Cap)

- ISO 7380 (Button head Socket Cap)

- DIN 7984 (Low head Socket Cap)

Cap Screws vs Socket Screws

| Features |

Cap Screws |

Socket Screws |

| Head type |

large, flat head with a hexagonal indentation on top |

cylindrical head with a hexagonal socket (Allen socket) |

| Thread Type |

full threads |

partial threads |

| Common Applications |

- construction

- industrial

- machinery

- automotive

|

- aerospace

- automotive

- electronics

- machinery

|

| Materials |

steel, stainless steel, brass etc |

steel, stainless steel, brass, etc |

| Drive types |

Hexagon / Square |

Allen |

| Strength |

high strength and durability |

high torque strength |

| Cost |

Less expensive |

more expensive due to precision machining and specific drive design |

Manufacturing Process Socket Head Cap Screws

- Material selection: stainless steel, alloy and superalloy

- Cold Forming: shaped at room temperature

- high-pressure technique

- Thread Cutting or Rolling

- Heat Treatment

- Finishing

Automotive Molding Parts

Automotive Molding Parts,Automotive Plastic Components,Automotive Plastic Part,Automotive Injection Molding Parts

Wisegroup Precison Mold Ltd , https://www.wisegroupasia.com