Short radius elbows, as the name suggests, are more compact in design. The term "short radius" refers to the bend radius of the elbow being equal to the pipe diameter. This makes them ideal for applications where space is limited or where a sharper turn is required. Although less commonly used than long radius elbows, they are often preferred in low-pressure systems due to their efficiency and ease of installation.

Table of contents

- SR Elbow Specification

- Short Radius 90 Degree Elbow Dimensions

- 45 Degree SR Elbow Dimensions

- ASME B16.9 Short Radius Elbow Dimensions Inches

- Short Radius Elbow Formula

- SS Short Radius Elbow Applications

- Long Radius VS Short Radius Elbow

- 90 Deg Short Radius Elbow Weight Chart

- Types of Short Radius Elbow

- Inconel Buttweld SR Elbow Tolerance

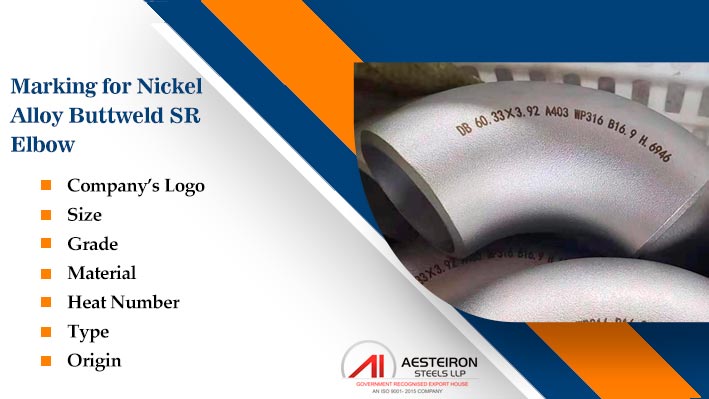

- Marking for Nickel Alloy Buttweld SR Elbow

- ANSI B16.9 SR Elbows Fittings Materials and Grades

ASME B16.9 SR Elbow Manufacturer in India

ASME B16.9 short radius elbows are typically available in 90-degree configurations. These fittings create a sharper turn compared to long radius elbows, making them suitable for tight spaces. They are manufactured according to the standards set by the American Society of Mechanical Engineers (ASME), which ensures quality and consistency in dimensions, pressure ratings, and material specifications.

Adhering to ASME B16.9 standards guarantees that these fittings meet rigorous requirements for durability, performance, and safety in various industrial applications.

SR Elbow Specification

| Short Radius Elbow Size |

- Seamless Elbow : 1/2 to 24 inch

- Welded Elbow : 1/2 to 48 inch

|

| ASME B16.9 Short Radius Elbow Manfacturing Type |

- Seamless

- Welded

- ERW

- Fabricated

|

| Thickness |

|

| Dimensions Standard |

- ASME B16.9

- MSS-SP-43

- ASME B16.28

|

| Type |

- 90 Degree

- 45 Degree

- 180 Degree

- 1D

- 3D

- 5D

|

| Short Radius Elbow 45 Degree Material |

- Stainless Steel

- Duplex & Super Duplex Steel

- Carbon Steel

- Alloy Steel

- Nickel Alloy

|

| 3/8 NPT Street Elbow Certificates |

- MTC EN 10204 3.1/3.2

- 100% Radiography Test Report

- Raw Materials Certificate

- Third Party Inspection Report

- NACE MR0175

- NACE TM-0284

- NACE MR0103

- ISO 15156

|

| 3/4 Street Elbow Origin |

- Japanese

- Korean

- Indian

- Russian

- Ukraine

- USA

- European

|

| 45 Deg SR Elbow Pressure Class |

|

| Connection Type |

|

| Short Radius Elbow Standard |

|

| Manufacturing Method |

- Pressing

- Hot Forming

- Hamming

- Flat rolling

- Pipe rolling

- Shape rolling

- Hot mandrel bending

- Piercing

|

| Thickness Tolerance |

|

| 90 Degree SR Elbow Testing |

- Ultrasonic test

- PMI

- HIC tested

- MT

|

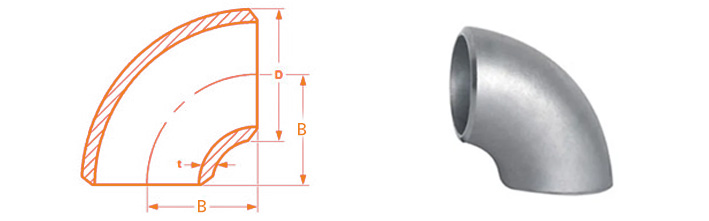

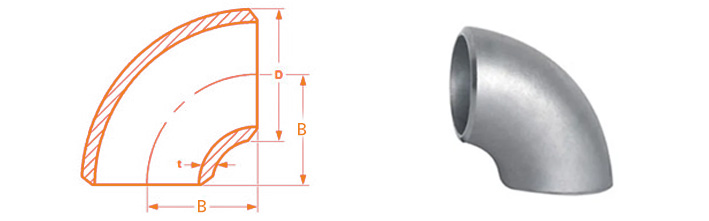

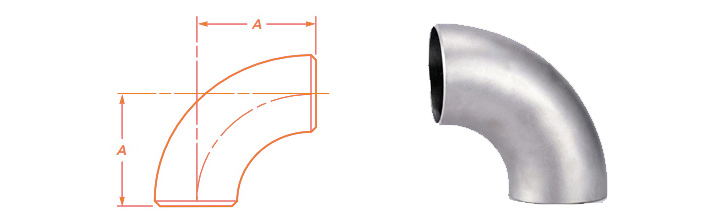

Short Radius 90 Degree Elbow Dimensions

| NPS in inch |

Center to End

B |

Outer Diameter

D |

| 1 |

25 |

33.4 |

| 1¼ |

32 |

42.2 |

| 1½ |

38 |

48.3 |

| 2 |

51 |

60.3 |

| 2½ |

64 |

73 |

| 3 |

76 |

88.9 |

| 3½ |

89 |

101.6 |

| 4 |

102 |

114.3 |

| 5 |

127 |

141.3 |

| 6 |

152 |

168.3 |

| 8 |

203 |

219.1 |

| 10 |

254 |

273 |

| 12 |

305 |

323.8 |

| 14 |

356 |

355.6 |

| 16 |

406 |

406.4 |

| 18 |

457 |

457 |

| 20 |

508 |

508 |

| 22 |

559 |

559 |

| 24 |

610 |

610 |

Short radius reducing elbows are manufactured in sizes from 1/2 to 48 inches

The wide range of sizes available for short radius reducing elbows allows for seamless connections between different pipe diameters in piping systems. This ensures smooth fluid flow and avoids restrictions, making them ideal for plumbing and industrial applications where multiple pipe sizes are involved.

The table below provides the dimensions and size range for short radius elbows.

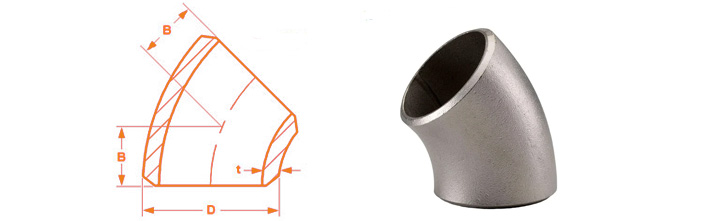

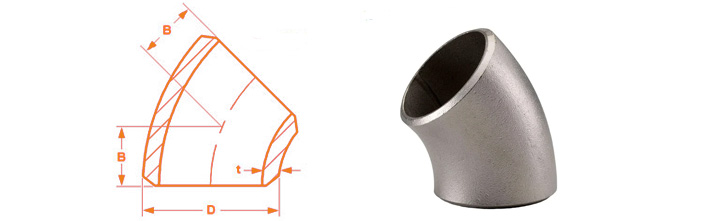

45 Degree SR Elbow Dimensions

| NPS in inch |

Outer Diameter

D |

45°

3D

Center to End

A |

45°

SR

Center to End

A |

| 1/2 |

21.3 |

– |

38 |

| 1 |

33.4 |

76 |

38 |

| 1½ |

48.3 |

114 |

57 |

| 2 |

60.3 |

152 |

76 |

| 3 |

88.9 |

229 |

114 |

| 4 |

114.3 |

305 |

152 |

| 6 |

168.3 |

457 |

229 |

| 10 |

273 |

762 |

381 |

| 14 |

355.6 |

1067 |

533 |

| 18 |

457 |

1372 |

686 |

| 22 |

559 |

1676 |

838 |

| 26 |

660 |

1981 |

991 |

| 30 |

762 |

2286 |

1143 |

| 34 |

864 |

2591 |

1295 |

| 38 |

965 |

2896 |

1448 |

| 42 |

1067 |

3200 |

1600 |

| 44 |

1118 |

3353 |

1676 |

| 46 |

1168 |

3505 |

1753 |

| 48 |

1219 |

3658 |

1829 |

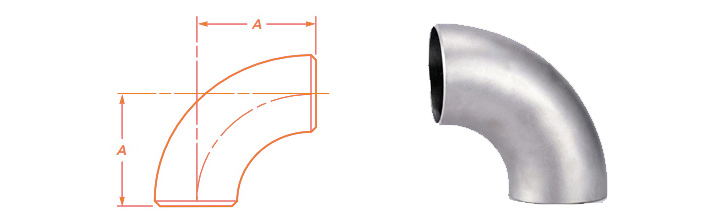

ASME B16.9 Short Radius Elbow Dimensions Inches

| Nominal Size |

OD at Bevel |

Center to End |

|

in. |

A

in. |

| 1 |

1.32 |

1 |

| 1 1/4 |

1.66 |

1.25 |

| 1 1/2 |

1.90 |

1.50 |

| 2 |

2.38 |

2 |

| 2 1/2 |

2.88 |

2.50 |

| 3 |

3.50 |

3 |

| 3 1/2 |

4 |

3.50 |

| 4 |

4.50 |

4 |

| 5 |

5.56 |

5 |

| 6 |

6.62 |

6 |

| 8 |

8.62 |

8 |

| 10 |

10.75 |

10 |

| 12 |

12.75 |

12 |

| 14 |

14 |

14 |

| 16 |

16 |

16 |

| 18 |

18 |

18 |

| 20 |

20 |

20 |

| 22 |

22 |

22 |

| 24 |

24 |

24 |

In SR Elbow, the radius is the same as the pipe diameter (R=D)

This means that the curvature of the short radius elbow matches the diameter of the pipe. It offers a compact and efficient change in the direction of fluid flow in piping systems. The same-size radius reduces the need for extra steps during installation while ensuring a smooth transition between the pipe and the elbow.

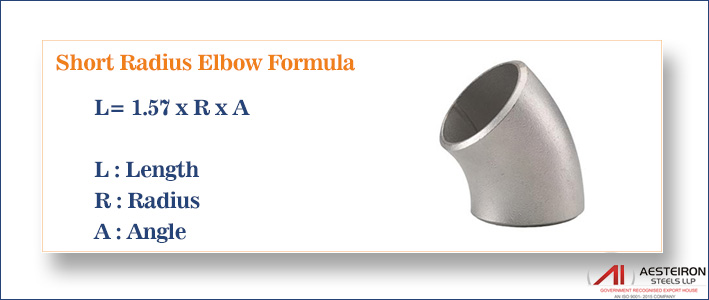

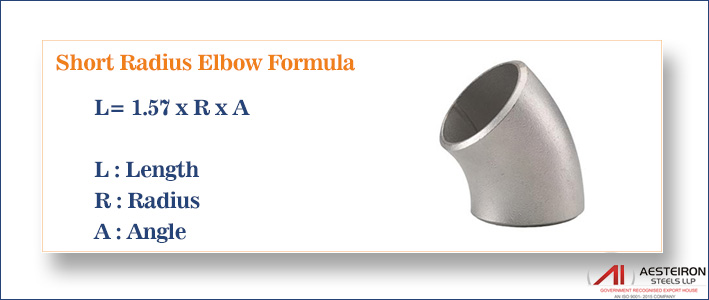

Short Radius Elbow Formula

90-degree short radius elbows are used in situations with sharp turns

The compact structure of this elbow allows it to fit into tight spaces, making it ideal for installations where there's limited room to maneuver. It also helps reduce the overall length of piping runs, which is essential for compressed or space-constrained piping systems.

SS Short Radius Elbow Applications

- Oil and Gas Pipeline

- Water Supply Systems

- Chemical Industry

- Power Plant

- Fabrication Industry

- Structural Pipe

- Paper & Pulp Industry

- Food Processing Industry

45-degree SR elbows cause a greater pressure drop compared to long-radius elbows

This results in less smooth fluid flow, which is why they are not as commonly used. However, they are still employed in applications where flow rate is not critical and where fluids travel over long distances or require multiple directional changes. These elbows introduce higher friction loss and are often used with larger pumping systems.

Long Radius VS Short Radius Elbow

| Description |

Long Radius |

Short Radius Elbow |

| Size |

1.5 times greater diameter |

1 times greater diameter |

| Bend radius |

Larger |

Smaller |

| Shape |

Flatter |

Compact |

| Appearance |

Curved curve |

Sharper curve |

| Flow resistance |

Lower resistance |

Higher resistance |

| Effects of fluid flow |

Smooth flow |

Turbulent flow |

| Application |

Chemical industry, oil and gas |

Used where turbulence is acceptable |

| Advantages |

Heavier and more durable |

Lighter and easier to install |

| Cost |

More expensive |

Less expensive |

| Pressure Loss |

High |

Low |

90 Deg Short Radius Elbow Weight Chart

| NPS |

Weight In Kilogram |

| 1/2 |

.08 |

| 1 |

.18 |

| 1 1/2 |

.41 |

| 2 |

.73 |

| 3 |

2.27 |

| 4 |

4.08 |

| 6 |

11.11 |

| 10 |

39.92 |

| 14 |

72.57 |

| 18 |

117.93 |

| 22 |

178.72 |

| 26 |

249.48 |

| 36 |

481.72 |

Types of Short Radius Elbow

Short Radius 90 Degree Elbow

45 Degree SR Elbow

3D Short Radius Elbows

ASME B16.9 5D Short Radius Elbow

Buttweld Short Radius Pipe Elbow

1.5D Schedule 10 SR Elbows

Inconel Buttweld SR Elbow Tolerance

| NPS |

32 to 48 |

26 to 30 |

20 to 24 |

10 to 18 |

OD

at Bevel (D) |

+ 6.4

– 4.8 |

+ 6.4

– 4.8 |

+ 6.4

– 4.8 |

+ 4

– 3.2 |

| ID at End |

4.8 |

3.2 |

| Center to End 3D (A/B) |

6 |

6 |

3 |

3 |

| Center to End LR (A/B) |

5 |

3 |

2 |

2 |

| NPS |

5 to 8 |

4 |

3 to 3.1/2 |

1/2 to 2.1/2 |

OD

at Bevel (D) |

+ 2.4

– 1.6 |

1.6 |

1.6 |

+ 1.6

– .8 |

| ID at End |

1.6 |

.8 |

| Center to End 3D (A/B) |

3 |

3 |

3 |

3 |

| Center to End LR (A/B) |

2 |

2 |

2 |

2 |

Marking for Nickel Alloy Buttweld SR Elbow

ANSI B16.9 SR Elbows Fittings Materials and Grades

| Material |

Standards and Grade |

| Carbon Steel Short Radius Elbow |

- ASTM A105

- ASTM A350 LF2

- ASTM A694.

- DIN 1.0402

- DIN 1.0619

|

| Alloy Steel Short Radius Elbow |

- ASTM A182 F5

- F9

- F11

- F22

- F91

|

| Stainless Steel Short Radius Elbow |

- ASTM A403 WP304

- F304L

- F316

- F316L

- F317 / 317L

- F321 / 321H

- F347

|

| Inconel 90 Degree Short Radius Pipe Elbow |

|

| Copper Nickel Short Radius 90 Degree Elbow |

- C70600 – 90/10

- C71500 – 70/30

|

| Hastelloy Short Radius Reducing Elbow |

|

| Nickel Alloy SR Elbow |

|

| Duplex Short Radius Elbow |

|

| Super Duplex SR 45 deg Elbow |

|

| Incoloy SR Elbow |

|

| Titanium Short Radius 90 Degree Elbows |

- Grade 1

- Grade 2

- Grade 4

- Grade 5

- Grade 7

|

Rubber Powder Grinder Machine

Rubber Powder Grinder Machine is used to grind rubber granules to rubber powders, the size of rubber powder can be controlled by adjusting the milling discs distance.

Rubber Powder Grinder Machine,Rubber Milling Machine,Rubber Fine Powder Machine,Rubber Discs Grinding Machine

WUXI DEIICHEN MACHINERY PTY.,LTD , https://www.dicmachine.com